Nke kacha mma na-ekpo ọkụ-mikpu galvanized warara nchara

Usoro mmepụta

Nkeji I

A ga-ekpocha eriri igwe ahụ niile ma mebie ya iji nweta elu na-egbuke egbuke ma dị ọcha.

Agba nke Abụọ

1.Hot-mikpu galvanizing: mgbe pickling, ọ na-ehicha ya site ammonium chloride ma ọ bụ zinc chloride aqueous ngwọta ma ọ bụ ammonium chloride na zinc chloride agwakọta aqueous ngwọta tank.Mgbe ahụ, a na-eziga ya na tank nke na-ekpo ọkụ na-ekpo ọkụ maka galvanizing.

2.Hot galvanizing: mgbe pickling, ọ na-kpochara na bath nke ammonium chloride ma ọ bụ zinc chloride aqueous ngwọta ma ọ bụ ammonium chloride na zinc chloride weere aqueous ngwọta, na mgbe ahụ zigara n'ime galvanizing bath mgbe na-aga n'ihu annealing ọkụ maka galvanizing.

3.Direct galvanizing: mgbe pickling, ọ na-eziga n'ime na-aga n'ihu annealing ọkụ wee banye galvanizing tank maka galvanizing.

Agba nke Atọ

Mgbe a na-agbanye ígwè nke warara ahụ, a ga-ejikọta ya ma tinye ya na nchekwa.The galvanized oyi akwa nwere ike ọ dịghị ihe na-erughị 50g / m2 dị ka ndị ahịa chọrọ, na ihe ọ bụla sample ga-abụ ihe na-erughị 48g / m2.

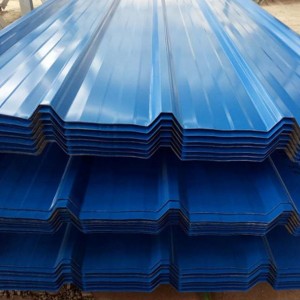

A na-ejikarị eriri galvanized emepụta ọkpọkọ ígwè, dị ka ọkpọkọ griin haus, ọkpọkọ mmiri ọṅụṅụ, ọkpọkọ kpo oku, na ọkpọkọ nnyefe gas;Enwere ike iji ya na ihe owuwu, ụlọ ọrụ ọkụ, ụgbọ ala, ọrụ ugbo, ịzụ ụmụ anụmanụ, ịkụ azụ, ịzụ ahịa na ụlọ ọrụ ndị ọzọ.

Galvanized ígwè warara na-egosi na a na-eji ụlọ ọrụ ihe owuwu na-emepụta ihe na-emepụta ihe na-eme ka ụlọ ọrụ na-emepụta ihe na-emepụta ihe na-eme ka ụlọ ọrụ na-emepụta ihe na-emepụta ihe na ụlọ ụlọ, ụlọ elu ụlọ, wdg;Ụlọ ọrụ ọkụ na-eji ya emepụta shei ngwa ụlọ, chimnis obodo, arịa kichin, wdg, ụlọ ọrụ ụgbọ ala na-ejikarị ya emepụta akụkụ ụgbọ ala na-eguzogide corrosion, wdg;A na-ejikarị ọrụ ugbo, ịzụ ụmụ anụmanụ na azụ azụ dị ka nchekwa nri na njem ụgbọ njem, ngwa eji ajụ oyi maka anụ na ngwaahịa mmiri, wdg;Azụmahịa, a na-ejikarị ya dị ka nchekwa, njem na nkwakọ ngwaahịa nke ihe;Ihe owuwu ígwè sandalwood mmanya (ụdị C, Z nchara);Igwe igwe anaghị agba nchara, mkpuchi elu ụlọ, wdg.

Ọkpụrụkpụ ekwe ekwe omume

| Ike mkpụrụ kacha ntaMpa | Ọkpụrụkpụ ahamm | Ọkpụrụkpụ ekwe ekwe omume | izi eziPT.A | Elu-nkenkePT.B | Obosara aha | ≤1200 | > 1200-≤1500 | >1500 | ≤1200 | 1200-≤1500 |

| <280 | s0,40 | ±0.05 | ±0.06 | ±0.03 | ±0.04 | |||||

| > 0.40-0.60 | ±0.06 | ±0.07 | ±0.08 | ±0.04 | ±0.05 | |||||

| > 0.60-0.80 | ±0.07 | ±0.08 | ±0.09 | ±0.05 | ±0.06 | |||||

| > 0.80-1.00 | ±0.08 | ±0.09 | ±0.10 | ±0.06 | ±0.07 | |||||

| > 1.00-1.20 | ±0.09 | ±0.10 | ±0.11 | ±0.07 | ±0.08 | |||||

| > 1.20-1.60 | ±0.11 | ±0.12 | ±0.12 | ±0.08 | ±0.09 | |||||

| > 1.60-2.00 | ±0.13 | ±0.14 | ±0.14 | ±0.09 | ±0.10 | |||||

| > 2.00-2.50 | ±0.15 | ±0.16 | ±0.16 | ±0.11 | ±0.12 | |||||

| > 2.50-3.00 | ±0.17 | ±0.18 | ±0.18 | ±0.12 | ±0.13 | |||||

| ≥280 | ≤0.40 | ±0.06 | ±0.07 | ±0.04 | ±0.05 | |||||

| > 0.40-0.60 | ±0.07 | ±0.08 | ±0.09 | ±0.05 | ±0.06 | |||||

| > 0.60-0.80 | ±0.08 | ±0.09 | ±0.11 | ±0.06 | ±0.06 | |||||

| > 0.80-1.00 | ±0.09 | ±0.11 | ±0.12 | ±0.07 | ±0.08 | |||||

| > 1.00-1.20 | ±0.11 | ±0.12 | ±0.13 | ±0.08 | ±0.09 | |||||

| > 1.20-1.60 | ±0.13 | ±0.14 | ±0.14 | ±0.09 | ±0.11 | |||||

| > 1.60-2.00 | ±0.15 | ±0.17 | ±0.17 | ±0.11 | ±0.12 | |||||

| > 2.00-2.50 | ±0.18 | ±0.19 | ±0.19 | ±0.13 | ±0.14 | |||||

| > 2.50-3.00 | ±0.20 | ±0.21 | ±0.21 | ±0.14 | ±0.15 |

| Ọnụ obosara mm | Ọdịiche obosara nke ekwe omume (mm) | Nkenkenke ziri ezi PW.A | Ezi nkenke PW.B | Uru kacha nta | Kachasị | Uru kacha nta | Kachasị |

| 2600-1200 | 0 | +5 | 0 | +2 | |||

| 1200-1500 | 0 | +6 | 0 | +2 | |||

| >1500 | 0 | +7 | 0 | +3 | |||

| Ngbanwe nke ogologo | |||||||

| Ogologo aha aha mm | Ngbanwe nke ogologo (mm) kwere ekwe | Normal precision PL.A | Advanced precision PL.B | Uru kacha nta | Kachasị | Uru kacha nta | Kachasị |

| =2000 | 0 | +6 | 0 | +3 | |||

| ≥2000 | 0 | Ogologo 0.3% | 0 | Ogologo ogologo 0.15% | |||

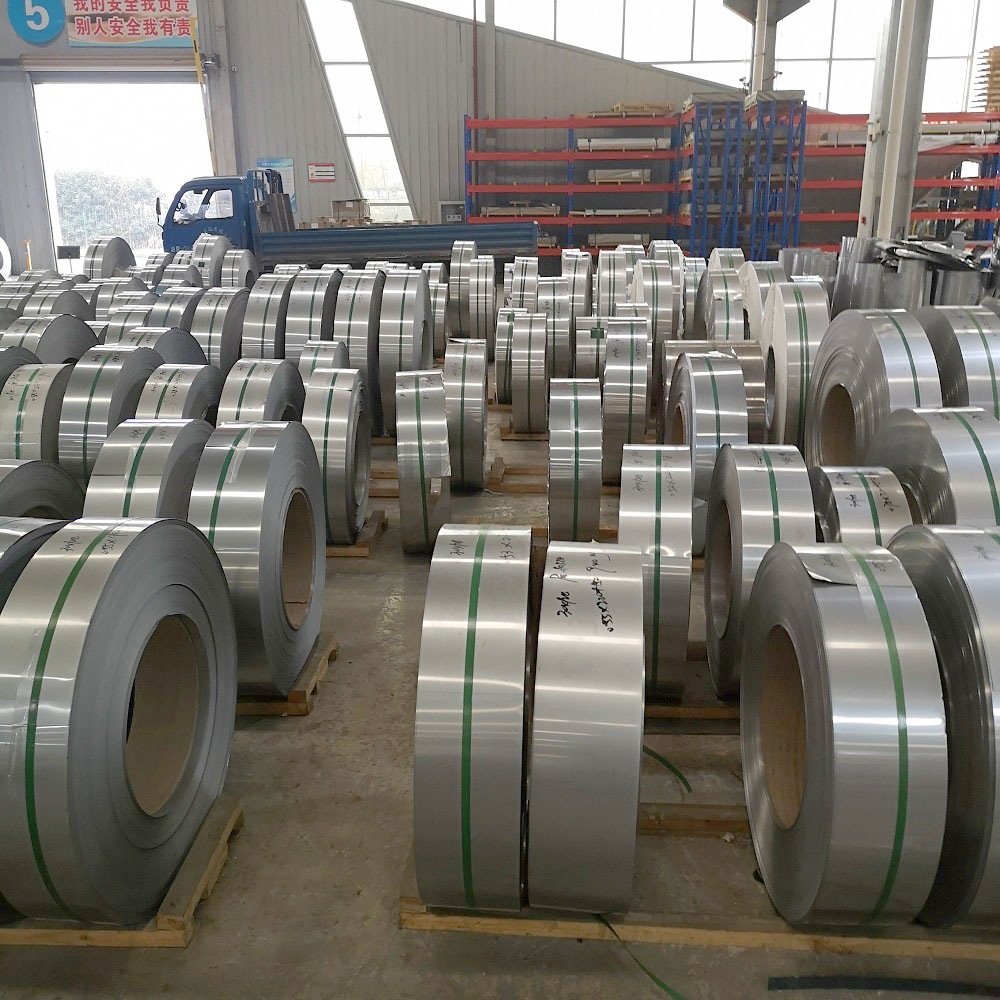

Eji Galvanized Steel Strip

A na-ejikarị eriri galvanized emepụta ọkpọkọ ígwè, dị ka ọkpọkọ griin haus, ọkpọkọ mmiri ọṅụṅụ, ọkpọkọ kpo oku, na ọkpọkọ nnyefe gas;Enwere ike iji ya na ihe owuwu, ụlọ ọrụ ọkụ, ụgbọ ala, ọrụ ugbo, ịzụ ụmụ anụmanụ, ịkụ azụ, ịzụ ahịa na ụlọ ọrụ ndị ọzọ.A na-ejikarị ụlọ ọrụ na-ewu ụlọ na-emepụta ihe mgbochi ụlọ ọrụ na-emepụta ihe na-eme ka ụlọ ọrụ na-emepụta ihe na-emepụta ihe na-eme ka ụlọ elu ụlọ, ụlọ elu ụlọ, wdg;Ụlọ ọrụ ọkụ na-eji ya emepụta shei ngwa ụlọ, chimnis obodo, arịa kichin, wdg, ụlọ ọrụ ụgbọ ala na-ejikarị ya emepụta akụkụ ụgbọ ala na-eguzogide corrosion, wdg;A na-ejikarị ọrụ ugbo, ịzụ ụmụ anụmanụ na azụ azụ dị ka nchekwa nri na njem ụgbọ njem, ngwa eji ajụ oyi maka anụ na ngwaahịa mmiri, wdg;Azụmahịa, a na-ejikarị ya dị ka nchekwa, njem na nkwakọ ngwaahịa nke ihe;Ihe owuwu ígwè sandalwood mmanya (ụdị C, Z nchara);Igwe igwe anaghị agba nchara, mkpuchi elu ụlọ, wdg.

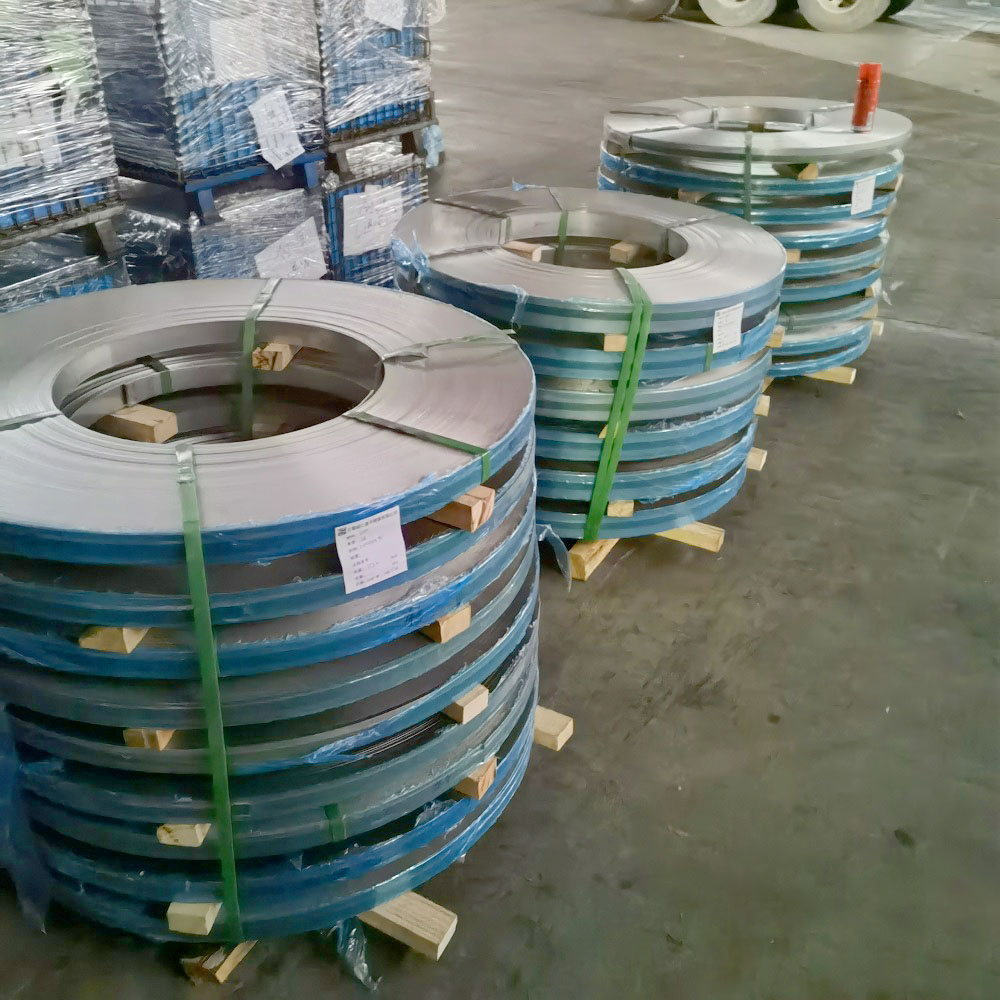

Akụkụ nke eriri galvanized steel strip: galvanized steel strip bụ ụdị akụrụngwa a na-akpọ (zinc) nke a na-etinye n'elu efere nchara dị ogologo ma dị warara nke mpịakọta oyi ma ọ bụ na-ekpo ọkụ.Hot galvanizing nwere uru nke mkpuchi uwe, ike nkedo na ogologo ndụ ọrụ.Mgbagwoju anya nke anụ ahụ na kemịkalụ dị n'etiti mkpụrụ ọkpọkọ ọkpọkọ na-ekpo ọkụ na-ekpo ọkụ na ihe ngwọta a wụrụ awụ na-etolite akwa zinc-ígwè alloy na-eguzogide corrosion na nhazi kọmpat.A na-ejikọta oyi akwa alloy na akwa zin c dị ọcha yana mkpụrụ nchara nchara.Ya mere, ọ nwere nguzogide corrosion siri ike.Isi ihe dị mma nke eriri galvanized ga-adị mma n'ile anya, na-enweghị zinc nodules na burrs, na ọlaọcha na-acha ọcha;Enwere ike ịchịkwa ọkpụrụkpụ, n'etiti 5-107 μ Nhọrọ ọ bụla n'ime m;Ọ dịghị hydrogen ebrittlement na okpomọkụ ihe ize ndụ, nke nwere ike hụ na n'ibu ihe onwunwe na-anọgide na-agbanweghi agbanwe;Ọ nwere ike dochie ụfọdụ usoro na-achọ ọkụ galvanizing;Ezigbo nguzogide corrosion, nnwale ịgba nnu na-anọpụ iche ruo awa 240;Etc Strip steel, nke a makwaara dị ka eriri igwe, dị n'ime 1300mm n'obosara, na ogologo ya dịtụ iche dịka nha nke eriri igwe ọ bụla.A na-enyekarị nchara nchara na eriri igwe, nke nwere uru nke nha nha dị elu, mma elu dị mma, nhazi dị mfe na nchekwa ihe.

Usoro mbukota: ngwugwu, osisi osisi

Ụdị mbupụ: njem ụgbọ ala

Ihe osise zuru ezu