Efere igwe anaghị agba nchara

Nkọwa ngwaahịa

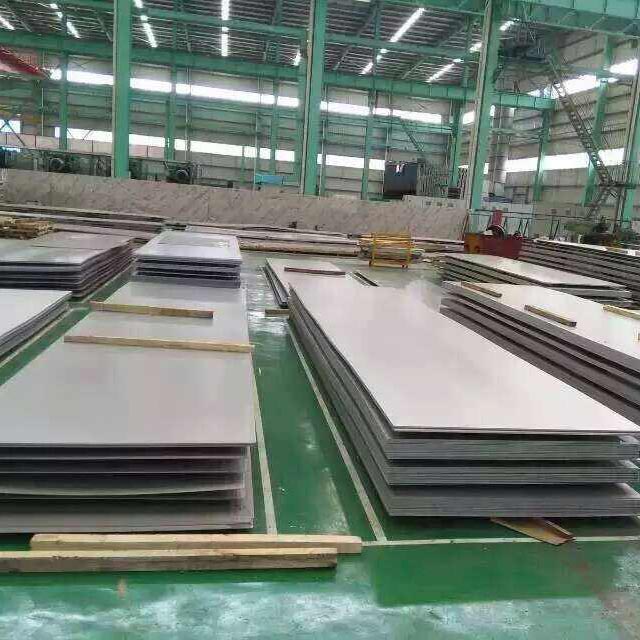

Dị ka usoro mmepụta si dị, e nwere ụdị abụọ na-ekpo ọkụ na-ekpo ọkụ na ntụgharị oyi, gụnyere mpempe akwụkwọ 0.5-4 mm na nnukwu efere 4.5-35 mm.

Dị ka ihe nhazi nke ígwè si dị, ọ nwere ike kewaa n'ime ụdị ise: austenite, austenitic-ferrite, ferrite, martensite na mmiri ozuzo hardening.

Jiri gburugburu ebe obibi: buru corrosion nke oxalic acid, sulfate-ferric sulfate, nitric acid, nitric acid-hydrofluoric acid, sulfate-ọla kọpa sulfate, phosphoric acid, formic acid, acetic acid na ndị ọzọ.

Na-eji: eji kemịkalụ, nri, ọgwụ, akwụkwọ, mmanụ, atomiki ike na ụlọ ọrụ ndị ọzọ, yana akụkụ dị iche iche na akụkụ nke ụlọ, kichinware, tableware, ụgbọ ala na ngwa ụlọ.Iji hụ na ike mkpụrụ, ike ike, elongation, ike siri ike na ihe ndị ọzọ na-arụ ọrụ nke igwe anaghị agba nchara dị iche iche na-eme ka ihe ndị a chọrọ, efere ígwè ahụ ga-enwerịrị nkwụsịtụ, ọgwụgwọ ngwọta, ọgwụgwọ ịka nká na ọgwụgwọ okpomọkụ ndị ọzọ tupu nnyefe.

Ihe achọrọ dị mma: efere igwe anaghị agba nchara nwere elu dị larịị, nnukwu plasticity, ike siri ike na ike n'ibu, ma na-eguzogide corrosion nke acid, alkaline gas, ngwọta na mgbasa ozi ndị ọzọ.Ọ bụ ígwè alloy nke na-adịghị mfe nchara, ma ọ bụghị nchara kpamkpam.The corrosion eguzogide nke igwe anaghị agba nchara tumadi dabere na ya alloy mejupụtara (chromium, nickel, titanium, silicon, aluminum, wdg) na esịtidem Ọdịdị.Isi ọrụ bụ chromium.Chromium nwere nnukwu nkwụsi ike nke kemịkalụ, nwere ike ịmepụta ihe nkiri passivation n'elu igwe, kewapụ ígwè ahụ n'èzí, chebe efere ígwè ahụ site na oxidation, ma mee ka mgbochi corrosion nke efere ígwè dị elu.Mgbe e bibisịrị ihe nkiri passivation, nguzogide corrosion ga-ebelata.

Ngwakọta kemịkalụ

| Koodu nkuzi jikọtara ọnụ | Ụdị | Ngwakọta kemịkalụ (irighiri oke)/% | ||||||||||||||||||||||||||||||||||

| c | Si | Mn | P | S | Ni | Cr | Mo | N | Cu | Ndị ọzọ | ||||||||||||||||||||||||||

| S30408 | 06Cr19Ni10 | 0.08 | 0.75 | 2.00 | 0,035 | 0.020 | 8.00-10.50 | 18.00-20.00 | 0.10 | |||||||||||||||||||||||||||

| S30403 | 022Cr19Nil0 | 0,030 | 0.75 | 2.00 | 0,035 | 0.020 | 8.00-12.00 | 18.00-20.00 | 一 | 一 | 一 | |||||||||||||||||||||||||

| S30409 | 07Cr19Ni10 | 0.04-0.10 | 0.75 | 2.00 | 0,035 | 0.020 | 8.00-10.50 | 18.00-20.00 | 一 | |||||||||||||||||||||||||||

| $31008 | 06Cr25Ni20 | 0.04-0.08 | 1.50 | 2.00 | 0,035 | 0.020 | 19.00-22.00 | 24.00-26.00 | ||||||||||||||||||||||||||||

| S31608 | 06Cr17Ni12Mo2 | 0.08 | 0.75 | 2.00 | 0,035 | 0.020 | 10.00-14.00 | 16.00-18.00 | 2.00-3.00 | 0.10 | 一 | |||||||||||||||||||||||||

| S31603 | 022Cr17Ni12Mo2 | 0,030 | 0.75 | 2.00 | 0,035 | 0.020 | 10.00-14.00 | 16.00-18.00 | 2.00-3.00 | 0.10 | 一 | |||||||||||||||||||||||||

| S31668 | 06Cr17Ni12Mo2Ti | 0.08 | 0.75 | 2.00 | 0,035 | 0.020 | 10.00-14.00 | 16.00-18.00 | 2.00-3.00 | 一 | 一 | Nke 5C | ||||||||||||||||||||||||

| S39042 | 015Cr21M26Mo5Cu2 | 0.020 | 1.00 | 2.00 | 0,030 | 0.010 | 24,00-26.00 | 19.00-21.00 | 4.00-5.00 | 0.10 | 1.20-2.00 | 一 | ||||||||||||||||||||||||

| S31708 | 06Cr19Ni13Mo3 | 0.08 | 0.75 | 2.00 | 0,035 | 0.020 | 11.00-15.00 | 18.00-20.00 | 3.00-4.00 | 0.10 | 一 | 一 | ||||||||||||||||||||||||

| S31703 | 022Cr19Ni13Mo3 | 0,030 | 0.75 | 2.00 | 0,035 | 0.020 | 11.00-15.00 | 18.00-20.00 | 3.00-4.00 | 一 | ||||||||||||||||||||||||||

| S32168 | 06Cr18Nil1Ti | 0.08 | 0.75 | 2.00 | 0,035 | 0.020 | 9.00-12.00 | 17.0-19.00 | Nke 5C | |||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||

| GB/T 20878 | Koodu nọmba ejikọtara ọnụ | Ụdị | Ngwakọta kemịkalụ (irighiri oke)/% | |||||||||||||||||||||||||||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | N | Ndị ọzọ | ||||||||||||||||||||||||||

| 68 | S21953 | 022Cr19Ni5Mo3S2N | 0,030 | 1.30-2.00 | 1.00-2.00 | 0,030 | 0.020 | 18.00-19.50 | 4.50-5.50 | 2.50-3.00 | 一 | 0.05-0.12 | 一 | |||||||||||||||||||||||

| 70 | S22253 | 022Cr22Ni5Mo3N | 0,030 | 1.00 | 2.00 | 0,030 | 0.020 | 21.00-23.00 | 4.50-6.50 | 2.50-3.50 | 0.08-0,20 | 一 | ||||||||||||||||||||||||

| 71 | S22053 | 022Cr23Ni5Mo3N | 0,030 | 1.00 | 2.00 | 0,030 | 0.020 | 22.00-23.00 | 4.50-6.50 | 3.00-3.50 | 一 | 0.14-0.20 | 一 | |||||||||||||||||||||||

| Ngwakọta kemịkalụ nke ụdị ụfọdụ dị na tebụl dị iche na nke GB/T 20878 | ||||||||||||||||||||||||||||||||||||

| GB/T 20878 | Koodu nkuzi jikọtara ọnụ | Ụdị | Ngwakọta kemịkalụ (irighiri oke)/% | |||||||||||||||||||||||||||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo | N | Ndị ọzọ | |||||||||||||||||||||||||||

| 78 | S11348 | 96C-13A | 0.08 | 1.00 | 1.00 | 0,035 | 0.020 | 11.50-14.50 | 0.60 | - | - | Al: 0.10 ~ 0.30 | ||||||||||||||||||||||||

| 92 | S11972 | 019Cr19Mo2NbTi | 0.025 | 1.00 | 1.00 | 0,035 | 0.020 | 17.50-19.50 | 1.00 | 1.75-2.50 | 0,035 | (Ti+Nb) [0.20+4 (C+N)] 0.80 | ||||||||||||||||||||||||

| 97 | S11306 | 06Cr13 | 0.06 | 1.00 | 1.00 | 0,035 | 0.020 | 11.50-13.50 | 0.60 | 一 | 一 | |||||||||||||||||||||||||

| Ngwakọta kemịkalụ nke ụdị ụfọdụ dị na tebụl dị iche na nke GB/T 20878 | ||||||||||||||||||||||||||||||||||||

Ọkpụrụkpụ Ọkọlọtọ

Obosara efere igwe anaghị agba nchara:

1000mm, 1220mm, 1250mm, 1500mm, 1800mm, 2000mm.

Na-abụghị efere ogologo: 1000mm, 1220mm, 1250mm, 1500mm, 1800mm, 2000mm nwere ike kpebisie ike dị ka ahịa chọrọ.

Akụkụ ntụgharị oyi:

Igwe anaghị agba nchara efere oyi akpọrepu 2B (coil, warara, ewepụghị efere) àgwà efere: 3 5mm-6mm 304/2B, 316L/2B.

Ọkpụrụkpụ: oyi akpọrepu 2B (0.1-6.0mm).

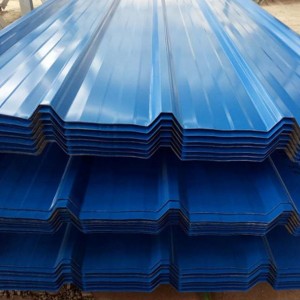

Elu: 2B dị larịị, BA.

8K mirror;Ịse waya na sanding;ájá snoo;Efere igwe anaghị agba nchara.

Ihe eji achọ mma: efere agba, efere titanium, efere etching, mmanụ na-egbuke egbuke ntutu ntutu (HL, NO.4), 3D efere atọ, efere ájá ájá, efere embossed.

Ngalaba na-ekpo ọkụ na-ekpo ọkụ: igwe anaghị agba nchara na-ekpo ọkụ na-atụgharị No.1 (coil, flat plate).

Ọkpụrụkpụ: ụlọ ọrụ mmepụta ihe No.1 (3-159mm).

Elu: 8K mirror elu;Ịse waya, titanium plating, sanding;ájá snoo;Efere igwe anaghị agba nchara.